charpy impact test google scholar|charpy impact test sample : manufacturing This paper reviews the historical development of the instrumented Charpy test and discusses load-energy-time parameters that can be determined to assess material strength . 24 de jan. de 2024 · Por fim, a KTO é outra excelente plataforma para você aproveitar o Fortune Mouse. O KTO oferece uma plataforma fácil de usar que combina uma seleção .

{plog:ftitle_list}

webVictory Casino Cruises. 180 Christopher Columbus Drive Cape Canaveral, FL 32920. (321) 684-5350 855-GO-VICTORY (468-4286)

This paper reviews the historical development of the instrumented Charpy test and discusses load-energy-time parameters that can be determined to assess material strength .The Charpy V-notch test has been used for a century now as an indirect, .

The use of an instrumented impact hammer on pre-cracked Charpy V specimens .Google Scholar provides a simple way to broadly search for scholarly literature. Search across a wide variety of disciplines and sources: articles, theses, books, abstracts and court opinions. The impact test method based on a pendulum, generally called the Charpy test, is one of the more cost-effective material testing procedures, both with respect to acceptance of .A 4 K Charpy test is defined as a Charpy test in which the initial temperature of a specimen is 4 K. Two methods, a glass Dewar method and a flow method, are compared in this study to .

The results obtained indicate that the equivalent strain rate for a Charpy test is far from material-independent, and can be very different from material to material. For the ten .

The paper presents and analyzes the results of experimental tests performed on two non-alloy low carbon steels (1.1141 and 1.0122) in cases of their exposure to impact .

Several researchers have recently employed the Charpy method to characterize the high strain rate mechanical strength of cementitious composites. This paper provides a critical . Charpy impact tests were simulated using the modified JC model and JC failure model with the determined parameters. Reasonable agreements between the simulation and .Impact tests yield absorbed energy values in excess of 300–400 J, which are associated with limited material fracture and mostly derive from plastic deformation of the specimen (bending), .

Charpy Impact Testing at 20°K. Conference paper. pp 56–62. Cite this conference paper. Download book PDF. Advances in Cryogenic Engineering. T. F. Kiefer, R. D. Keys & F. R. . What is the Charpy impact test used for? The purpose of the impact test is to assess the response of a known material, such as polymers, ceramics, and composites when subjected to sudden stress. It specifically .

Steel—Charpy V-Notch Pendulum Impact Test—Instrumented Test Method. International Standards Organization; Geneva, Switzerland: 2015. Standard No. ISO 14556. [Google Scholar] 8. ASTM. . [Google Scholar] 22. Doig P, Smith RF, Flewitt PEJ. The Use of Stretch Zone Width Measurements in the Determination of Fracture Toughness of Low Strength .

The Charpy impact test is carried out in a 3-point flexure setup.The Charpy specimen is centered on the supports in the pendulum impact tester and rests against two anvils. In the case of notched specimens, the notch faces away . [1] Garcia A, Spim J and Santos C A 2012 Ensaio dos Materials (Rio de Janeiro: LTC) 2 Google Scholar [2] ASTM International 2007 ASTM E23: Standard Test Methods for Notched Bar Impact Testing of Metallic Materials Google Scholar [3] Associação Brasileira de Normas Técnicas 2005 NBR ISO/IEC 17025 Requisitos gerais para a competência de .

DOI: 10.1016/S0029-5493(99)00017-5 Corpus ID: 111273928; Mechanical aspects of the Charpy impact test @article{Rossoll1999MechanicalAO, title={Mechanical aspects of the Charpy impact test}, author={Andreas Rossoll and Clotilde Berdin and Pierre Forget and Claude Prioul and Bernard Marini}, journal={Nuclear Engineering and Design}, year={1999}, volume={188}, .Charpy impact testing was performed on the series of machined specimens with sub-size cross-section to obtain values of CVN impact energy. Fracture toughness test method according to ASTM E1820 was performed on SENB specimens, fatigue pre-cracked, to obtain values of KIC. . Google Scholar [7] C., R. Hoffman, Interpretive report on small-scale .

Abstract. Several researchers have recently employed the Charpy method to characterize the high strain rate mechanical strength of cementitious composites. This paper provides a critical review of existing applications of the Charpy method for impact testing of cementitious composites. Studies have employed various specimen sizes and geometries. . Abstract. This paper is focused on the approximation of absorbed Charpy impact energy-temperature curves (KV-T) and the management of sub-size test piece results in Charpy pendulum impact tests. Both subjects are frequently underestimated but may have a strong impact on the assessment of product quality and structural integrity. The status of related test .

charpy impact test standard pdf

Google Scholar [7] Corwin W R and Houghland A M 1986 Effect of Specimen Size and Material Condition on the Charpy Impact Properties of 9Cr1MoVNb Steel ASTM, STP 888 325-338. Google Scholar [8] Louden B S, Kumar A S, Garner F A, Hamilton M L and Hu W L 1988 The Influence of Specimen Size on Charpy Impact Testing J. Nucl. Mat. 155 662-667 . Charpy impact test properties of ferritic steels show a transitional behaviour with temperature from a lower shelf representing fully brittle fracture to an upper shelf representing fully ductile fracture. When Charpy impact test data is available over the whole transition region, the data can be fitted by a sigmoidal function.Google Scholar Viehrig, H.-W., Boehmert, J. and Dzugan, J. Use of instrumented Charpy impact tests for the dtermination of fracture toughness values. From Charpy to Present Impact Testing (Selected papers from Charpy Centenary Conference-2001, Poitiers, France, Oct. 2-5, 2001) (Eds.) D. Francois and A. Pineau. ESIS Publication No. 30.In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture.Absorbed energy is a measure of the material's notch toughness.It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and .

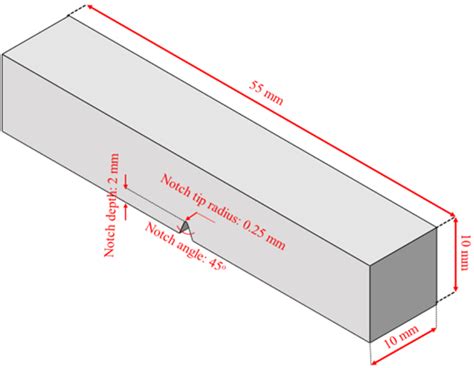

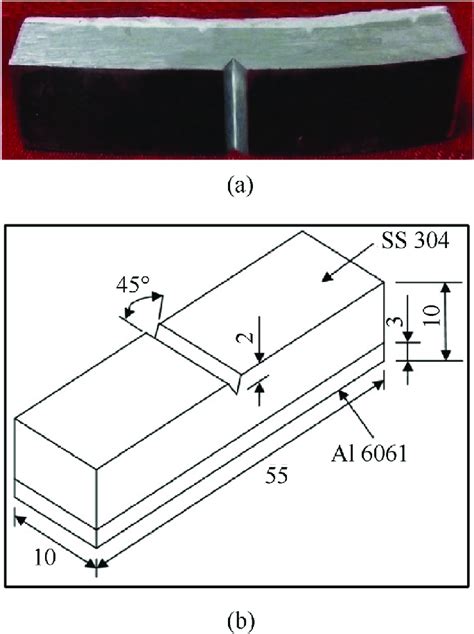

The Charpy impact test was conducted to examine the influence of salt spray. The impact strength CVN show decreasing trend with increase in exposure hours. . Google Scholar [2] H. Jafari, H. Mansouri, M. Honarpisheh. Investigation of residual stress distribution of dissimilar Al-7075-T6 and Al-6061-T6 in the friction stir welding process . Abstract. Several researchers have recently employed the Charpy method to characterize the high strain rate mechanical strength of cementitious composites. This paper provides a critical review of existing applications of the Charpy method for impact testing of cementitious composites. Studies have employed various specimen sizes and geometries. .In order to develop the small specimen technology in Charpy impact testing, the effects of V-notch dimensions on the test results were investigated for miniaturized specimens of a ferritic steel, Japanese Ferrite/Martensite Dual Phase Steel (JFMS). The miniaturized Charpy specimens had four different square cross-sections of 3.3, 2, 1.5 and 1 mm, and each of them had a .This "Cited by" count includes citations to the following articles in Scholar. The ones marked * may be different from the article in the profile. Add co-authors Co . Experimental investigation and statistical modeling of the effective parameters in charpy impact test on AZ31 magnesium alloy with v-shape groove using taguchi method. MR Maraki .

It would be therefore very desirable to measure the actual fracture toughness of very-high-toughness steels by means of an alternative specimen and/or methodology, entailing just a moderate increase of cost and test complexity with respect to Charpy testing.Google Scholar Tvergaard, V. and A. Needleman: 1993, ‘An analysis of the brittle–ductile transition in dynamic crack growth’. International Journal of Fracture 59, 53–67. Google Scholar Tvergaard, V. and A. Needleman: 2000, ‘Analysis of the Charpy V–notch test for welds’.Presents worldwide research on the factors and variables of the Charpy test. Consists of 12 papers in sections on The Pendulum-Impact Machine; Skip to Main Content. Close. . Google Scholar. ISBN-10: 0-8031-1295-5. ISBN: 978-0-8031-1295-7. No. of Pages: 226. . Charpy Impact Test: Factors and Variables. 100 Barr Harbor Drive, PO Box C700, .

Digital CROCKMETER commercial

DOI: 10.1007/978-3-319-95879-8_14 Corpus ID: 139370766; Numerical Modeling of Charpy Impact Test to Determine the Fracture Characteristics of Aluminium Alloy 6061 @article{Pervaiz2018NumericalMO, title={Numerical Modeling of Charpy Impact Test to Determine the Fracture Characteristics of Aluminium Alloy 6061}, author={Salman Pervaiz and . The purpose of this recommended practice guide is to demonstrate how to determine the uncertainty associated with mean absorbed energy of specimens tested on a Charpy impact machine. We assume that the Charpy machine has successfully met the requirements for both direct and indirect verification as described in the ASTM E 23, Standard . The V-notched Charpy impact test specimens were extracted from T6 heat-treated A356 aluminum alloy wheels. These specimens were tested with an instrumented Charpy V-notched impact tester after being conditioned at temperatures of − 75, − 40, 0, 20, 60, 95, and 175 °C. . Article Google Scholar O. Özaydın, A.Y. Kaya, D. Dispinar, Effect .

Therefore, this work aims to provide a new and practical testing procedure for sheet material or thin walled structures. The new testing procedure is based on tensile tests conducted in an impact pendulum similar to the Charpy impact hammer. A new standard geometry is provided, which enables a comparison between different steels or steel grades. View PDF View article View in Scopus Google Scholar [3] R.O. Ritchie. The conflicts between strength and toughness. Nat Mater, 10 (2011), pp. 817-822. . Fracture toughness-Charpy impact test-rockwell hardness regression based model for 51CrV4 spring steel. Mater Sci Tech, 30 (2013), pp. 1500-1505. Google Scholar. Cited by (0) The impact test method based on a pendulum, generally called the Charpy test, is one of the more cost-effective material testing procedures, both with respect t . charpy impact testing, history of material testing, instrumented impact testing, pendulum impact. Metals. . Google Scholar; BibTeX; RIS; Issues. If you have any questions about . It has passed one century since French G. Charpy proposed the Charpy impact test in 1901. Instrumented impact test recording load history during fracture has been attempted since 1920's. It has become possible to obtain various information from this method. However, succeeding development of fracture mechanics has made it also as a qualitative screening .

Therefore the present work evaluates the Charpy impact resistance of epoxy matrix composites, reinforced with 10, 20 and 30% in volume of continuous and aligned malva fibers (Urena Lobata, L). The impact tests were performed on standard specimens obtained by pressing mold and then cured for 24 hours.

Artificial Light Color Fastness Tester commercial

O Estádio Inca Garcilaso de la Vega é um estádio localizado na cidade de Cuzco, no Peru. Inaugurado em 1950, tinha capacidade para 22.000 torcedores, mas para ser uma das sedes da Copa América 2004 teve sua capacidade ampliada para 42.000 lugares.

charpy impact test google scholar|charpy impact test sample